- Monday 8:00AM - 5:00PM

- Tuesday 8:00AM - 5:00PM

- Wednesday 8:00AM - 5:00PM

- Thursday 8:00AM - 5:00PM

- Friday 8:00AM - 5:00PM

- Saturday Closed

- Sunday Closed

2024 John Deere 4075R

|

|

The bold styling of the tractor provides an attractive and functional appearance similar to that of the larger agricultural tractors. Benefits of this styling include:

The result gives the tractor a distinctive appearance and feel. | ||||||||||||||||||||||||||||||||

|

The Yanmar diesel engine has a high-torque reserve that provides plenty of power under heavy load.

*Engine hp (kW), gross SAE J1995: 43.1 (31.7) at 2600 rpm, PS The electronic control unit (ECU) provides optimum fuel control and accuracy. ECU monitors and controls the engine. It continuously monitors engine conditions and adjusts the fuel delivery accordingly to ensure optimum performance and emissions. The new engine comes with an after treatment system. The system operates automatically. The exhaust filter consists of a diesel particulate filter (DPF) which captures particulate matter (PM) contained in the exhaust gas. Using a natural cleaning process, most of the PM trapped in the exhaust filter is eliminated by the heat of the exhaust stream generated by normal use. In situations of low temperature, engine speed or load factor, an active cleaning cycle is initiated. In this cleaning cycle, the exhaust gas temperature is raised by injecting additional fuel during the exhaust stroke of normal vehicle operation to the diesel oxidation catalyst (DOC). After many hours of use, the exhaust filter may require an ash removal service. NOTE: *As compared to engines not using CRS technology. DPF CLEANINGDepending on the load that the tractor is under, as well as ambient temperature, humidity, and engine speed, the DPF may build up with particulate matter, thus requiring cleaning. Filter cleaning is determined by one of three conditions:

Once one of the three conditions has been met, filter cleaning will occur.

Passive filter cleaning Passive filter cleaning occurs naturally when the engine is generating enough heat to oxidize particulate matter. This automatic process occurs continuously during normal operating conditions. No tractor icons or symbols appear on the display during passive filter cleaning. NOTE: Passive filter cleaning requires no operator involvement, and there is no interruption to tractor operation. Active filter cleaning If conditions (temperature, load, or speed) for passive filter cleaning cannot be achieved, then PM is removed using active filter cleaner. To achieve the required conditions, exhaust temperature management (ETM) manages the initiation and duration of active filter cleaning. ETM can adjust numerous engine parameters and/or inject a small quantity of fuel into the exhaust stream for a short duration. The fuel turns to vapor and chemically reacts with the catalysts in the DOC to create heat to oxidize PM. It is important to note that at no time is the fuel in the DOC/DPF ignited, and there is no flame within the DOC/DPF. Like passive filter cleaning, active filter cleaning requires no operator involvement, and there is no interruption to tractor operation. Parked filter cleaning In some instances where passive and active filter cleaning have not fully cleaned the PM from the system, a parked filter cleaning may need to take place. Most likely, the only time a parked filter cleaning will need to occur is when automatic filter cleaning has been disabled for an extended period of time and multiple warnings to engage filter cleaning were ignored or if the tractor has been used during light load conditions. Additionally, when the automatic filter cleaning process has been deliberately interrupted multiple times, or if active filter cleaning has failed numerous times due to a failed component, a parked filter cleaning may be requested. In these rare instances the operator will have to park the tractor and start the filter cleaning process. The parked filter cleaning process needs to be activated based on usage and operation of the tractor. The process will take approximately 30 minutes. See operator’s manual for more details. This system constantly monitors the soot level of the tractor, making sure the tractor is always in peak performance condition. This ensures high performance at all times.

NOTE: Number of hours since last regeneration and soot level percentage viewable on LCD display.

Yanmar is a trademark of Yanmar Company Limited. | ||||||||||||||||||||||||||||||||

|

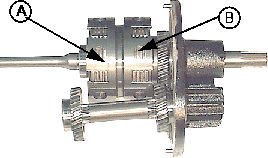

PowrReverser™ transmission allows for clutchless direction changesThe 12/12 PowrReverser transmission is available on the 4M and 4R Tractors.

The PowrReverser transmission features a hydraulically actuated wet clutch. Two multi-disk clutch packs (one forward and one reverse) are hydraulically engaged when the directional (reverser) lever is placed in either the forward or reverse position.

| ||||||||||||||||||||||||||||||||

|

PowrReverser™ transmission allows for clutchless direction changes

| ||||||||||||||||||||||||||||||||

|

Maximize productivity with an eHydro™ transmission

| ||||||||||||||||||||||||||||||||

Safety features of the eHydro transmission include:

| ||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||

Operator station is comfortable and convenient

Retractable seat belts prevent belts from becoming tangled in seat suspension and controls

Key features of the operator's station include: Large grab handles on each fender make getting on and off the tractor easy. Controls are shape and color-coded for easier identification and operation. Optional mechanical suspension seat improves operator comfort and reduces fatigue.

| ||||||||||||||||||||||||||||||||

|

Built-in safety features for operator peace of mind

| ||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||

Excellent serviceability reduces operational costs and improves productivityRegular service and maintenance are essential to the performance, productivity, and longevity of the tractor.

All items in the daily service schedule can be performed without the use of tools:

|

| Engine power (gross) | SAE J1995 rated power: 55.6 kW 74.6 hp 75.6 PS at 2600 rpm |

|---|---|

| Power take-off (PTO) power | eHydro™ transmission: 44.7 kW 60 hp Per SAE J1995 |

| Steering hydraulics | 23.5 L/min 6.2 gpm |

| Implement hydraulics | 42.3 L/min 11.2 gpm |

| Hitch type | Category 1 |

| Lift capacity, 24-in. behind link arms | 1229 kg 2709 lb |

| Standard transmission; forward/reverse | eHydro Transmission (eHST) |

| Cruise control | Standard |

| Approximate shipping weight (open-station; cab) | Cab - 2120 kg 4675 lb |

| Wheelbase | 1850 mm 73 in. |

| Family | EYDXL2.09HDA FYDXL2.09HDA GYDXL2.09HDA |

|---|---|

| Manufacturer | Yanmar |

| Engine model | 4TNV86CHT-MJT |

| Engine power (gross) | SAE J1995 rated power: 55.4 kW 74.3 hp 65.9 PS at 2600 rpm |

| Power take-off (PTO) power | eHydro transmission: 38.7 kW 51.9 hp |

| Rated engine speed | 2600 rpm |

| Type | Diesel |

| Injection pump type | Direct Injection |

| Aspiration | Turbocharged and Intercooled |

| Emissions compliance | Final Tier 4 |

| Cylinders/displacement | 4 / 2.091 L 4 / 127.6 cu in. |

| Number of cylinders | Four |

| Cylinder liners | Cast-in-block |

| Bore and stroke | 86 x 90 mm 3.4 x 3.54 in. |

| Compression ratio | 17.3:1 |

| Lubrication | Pressurized |

| Cooling system | Liquid |

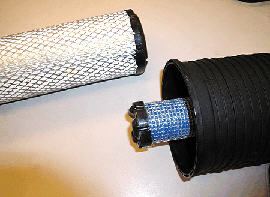

| Air cleaner | Dry Type with Electronic Restriction Indicator |

| Engine torque at rated speed | 205 Nm |

| Fuel tank capacity | 55.58 L 14.7 U.S. gal. |

| Battery size | 770 CCA |

|---|---|

| Alternator (12-V) | 75 amp |

| Starter size | 2 kW 2.68 hp |

| Type | High pressure common rail direct injection |

|---|

| Standard transmission; forward/reverse | eHydro transmission (eHST) |

|---|---|

| Optional transmission; forward/reverse | No |

| Left-hand reverser | No |

| Transmission gear ranges | eHydro - Infinitely-variable 3 range |

| Final drive | Planetary |

| Brakes | Multi-plate wet disc |

| Steering | Hydrostatic power steering |

| Axle capacity | Front 1600 kg 3528 lb Rear 2400 kg 5292 lb |

| Creeper | SpeedMatch standard |

| Cruise control | Standard |

| Differential lock | Yes |

| Type | Open center |

|---|---|

| Pump rated output | Steering 23.5 L/min 6.2 gpm Implement 42.3 L/min 11.2 gpm 65.8 L/min 17.4 gpm |

| Pump type | Single gear |

| Draft control sensing | Position control |

| Remote control valves available | Up to six rear remotes |

| Type | Category 1 |

|---|---|

| Lift capacity, 24-in. behind link arms | 1135 kg 2500 lb |

| Standard | Independent 540 rpm at 2600 rpm |

|---|---|

| Control | Position |

| Clutch | Wet disc |

| Crankcase with filter | 5.4 L |

|---|---|

| Transmission and hydraulic system | 47.3 L 12.5 gal. |

| Type | Planetary |

|---|---|

| Differential lock | Yes |

| Rollover protective structure | Type Fixed Yes |

|---|---|

| Platform - flat/straddle | N/A |

| Gear shift location - console/floor | No |

| Wheelbase | 185.5 cm 73 in. |

|---|---|

| Front axle clearance | 35.1 cm 13.8 in. |

| Turning radius with brakes | 3.19 m |

| Turning radius without brakes | 3.2 m |

| Approximate shipping weight (open-station; cab) | Cab - 2120 kg 4675 lb |

| Front | Farm - 8-16 Turf - 27x10.5-15 or 27x12LL-15 Industrial - 10-16.5 |

|---|---|

| Rear | Farm - 13.6-28 Turf - 44x18-20 or 22.5LL-16.1 Industrial - 16.9Lx24 |

| Front tread range | 148.1 cm 58.3 in. |

| Rear tread spacing | 137.2 cm 54 in. |

Dry-type air cleaner

Dry-type air cleaner

Helical-cut gears

Helical-cut gears Danfoss eHydro transmission

Danfoss eHydro transmission OPTIONAL CRUISE CONTROL

OPTIONAL CRUISE CONTROL Retractable seat belts

Retractable seat belts Comfortable and convenient design

Comfortable and convenient design

Removable side panels

Removable side panels Integrated grille maintenance position

Integrated grille maintenance position Removable cowl

Removable cowl