|

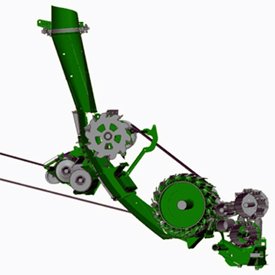

Optimal design and positioning of components increases crop delivery performance Optimal design and positioning of components increases crop delivery performance

ProStream Crop Flow

A key concept for the 8000 Series Self-Propelled Forage Harvester (SPFH) line was to position all crop-flow components to avoid any restrictions, as well as to design the crop path for minimum kinetic friction on the particles.

The 8000 Series crop-flow channel begins at the harvesting unit pickup tines or crop-row pointer. On the actual harvester, it starts with the feedroll arrangement. John Deere has implemented a concept layout well proven on the 7000 Series.

Key characteristics are a set of front feedrolls where, when the header interface is in a vertical position; the upper-front feedroll (UFFR) reaches out about 60 mm (2.4 in) over the crop in front of the lower one, grabbing the mat from the harvesting header and pulling it into the feedroll gap. This is a key function when corn headers without feed augers are mounted; assuring the machine’s crop feeder is the sole length-of-cut (LOC) metering unit of the harvester.

On its way to the cutterhead, the radial-arc-feed roll arrangement applies pressure to the crop for superior cut quality. The crop mat is perfectly compressed until the last second before transitioning into the knives.

From the moment the knife pockets start unloading, the cutterhead band takes the crop particle stream, collecting it for launching into the crop chute.

The crop path follows a constant curve between the cutterhead floor and the accelerator entrance. The crop accelerator, the spout transition, and the spout build the machine’s crop discharge device. All components that have an acceleration impact on the crop perfectly integrate tangentially into this curve for a fully unobstructed crop flow.

With 1800 rpm, the accelerator provides sufficient thrust to the crop stream for loading with the largest of heads without consuming excessive power. Rather than being carried by the accelerator rotor, the crop follows the curve of the accelerator band before moving through the transition directly into the spout base, from where on it follows the spout contour.

The crop hits the transition front liner just below the spout entrance at a shallow angle, minimizing component wear and inertia losses. This constant flow curve was designed to the spout as gently as possible so that the crop flow components had the least friction effect on the crop particles.

Sufficient space on the vehicle for a cab that allows for more operator leg room, though keeping the overall machine compact, was a key demand.

Ultimately, the 8000 Series SPFHs provide superior crop-flow efficiency, resulting in industry-leading machine capacity in respective horsepower classes as well as low-specific-fuel consumption (amount of diesel per ton of crop harvested). Combined with Dura Line™ technology, the 8000 Series SPFH triggers the lowest possible machine maintenance with minimal cost of operation.

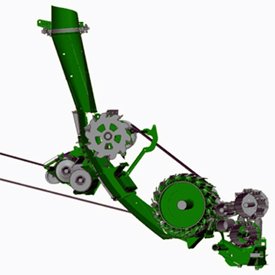

Crop accelerator

On its way to the trailer, the crop must be elevated more than 4 m (13 ft) high between the accelerator exit and the spout end. It must overcome a certain friction along the transition and spout liners until it is ejected off the spout end cap. When opening corn fields, producers can expect crop being airborne over a distance of 15 m to 20 m (50 ft to 65 ft) into the following trailer.

It is the task of the crop accelerator to provide sufficient thrust with appropriate efficiency to the crop particles to be loaded in all circumstances. An exactly specified air inlet in the accelerator housing assures a perfect spout crop jet when the kernel processor is installed.

Crop transition

The crop transition is completely lined with high-grade wear elements, which can easily be inspected and replaced from the machines service compartment through an access hatch. A unique manufacturing process allows even, customized hardening of the wear liners, perfectly addressing the individual wear situation in the cone. The transition is bearing the massive head gear-driven spout turning mechanism.

8000 Series SPFH features a spring-loaded cam-torque limiter inside the spout-turning drive mechanism. The spout hitting an obstacle is perfectly secured. However, the spout would never rotate uncontrolled and hit the cab. The spout turning sensor precisely monitors the spout position even when the spout clutch would have been triggered and mechanical end stops additionally secure the system. |

Advanced comfort and serviceability improve performance and uptime

Advanced comfort and serviceability improve performance and uptime Heavier designed components increase reliability while improving uptime and lowering cost of operation

Heavier designed components increase reliability while improving uptime and lowering cost of operation Optimal design and positioning of components increases crop delivery performance

Optimal design and positioning of components increases crop delivery performance Maximize animal performance through forage quality

Maximize animal performance through forage quality Best-in-class power efficiency delivers unmatched performance in the field

Best-in-class power efficiency delivers unmatched performance in the field

ProDrive™ system coupled with large tires boost performance and uptime in soft conditions

ProDrive™ system coupled with large tires boost performance and uptime in soft conditions Total Care

Total Care