2025 John Deere 8500

|

|

|

Specifications

|

Model |

8000 Series

|

Category Name |

Agriculture

|

Year |

2025

|

|

Sale Type |

New

|

Manufacturer |

John Deere

|

Price |

Contact for price CAD

|

|

|

|

Description

- 585 hp FT4 John Deere engine.

- All-new design delivers improved serviceability with an integrated KP hoist, easy header hook-up and ground level fuel fill.

- A best-in-class cab offers easier to use controls, better display access and visibility.

|

|

|

|

FEATURES

|

Features

|

Advanced comfort and serviceability improve performance and uptime Advanced comfort and serviceability improve performance and uptime

Cooling package serviceability

The entire cooling package for the 8000 Series Self-Propelled Forage Harvester (SPFH) cooling system can be accessed from the service compartment in the middle of the machine. Everything can be reached easily in one spot on the machine, making daily servicing convenient. The constantly rotating radiator screen allows a wide opening angle for easier service. No tools are required for servicing the air filters. The filters can be reached when standing on the left side of machine in the service room.

Fuel tank

The standard 1100-L (290.6-gal.) fuel tank and 43-L (10.6-gal.) urea tank are located in the center on the left-hand side of the machine. This guarantees a low center of gravity. Both tanks’ filler necks are accessible from the cab stairs. Refueling is done from one single position.

- High power density and great fuel efficiency

- Constant maximum power down to lower engine rpm

- Torque curve designed for forage harvesting applications

Cutterhead access

The 8000 Series cutterhead unit concept provides two methods to access the shear bar and cutterhead for inspection or maintenance.

Leaving the header mounted on the machine and releasing the top locking mechanism together with the top side pivot pin, while the lower clamps remain locked, allows access to the shear bar and the knives through a 35-degree V-opening.

Detaching the header and releasing the upper and the lower locking mechanisms, provides convenient access through a feedroll door opening action, similar to the 6000 and 7000 Series Harvesters.

|

|

Heavier designed components increase reliability while improving uptime and lowering cost of operation Heavier designed components increase reliability while improving uptime and lowering cost of operation

Capacity, harvesting quality, machine efficiency, and total cost of ownership have always been important differentiators for self-propelled forage harvesters (SPFH). Machine size, weight, or soil compaction associated with weight, and tire size is critical to producers' acceptance of certain machines on their fields. A key demand on the 8000 Series was to find a machine layout for optimum weight distribution and maximum capacity potential.

The driveline concept has been optimized for maximum flexibility in setting the individual component speeds and also synchronizing certain functions for maximum harvesting quality. Specific component design has been implemented to improve efficiency.

Components have been laid out for matching the power demand, not only of today’s producers, but also meeting potential requirements of future users.

Most advanced wear-resistance technology is applied on all crop-flow elements to assure full-season harvesting uptime. Longer component wear life significantly lowers the cost of ownership.

|

|

Optimal design and positioning of components increases crop delivery performance Optimal design and positioning of components increases crop delivery performance

ProStream Crop Flow

A key concept for the 8000 Series Self-Propelled Forage Harvester (SPFH) line was to position all crop-flow components to avoid any restrictions, as well as to design the crop path for minimum kinetic friction on the particles.

The 8000 Series crop-flow channel begins at the harvesting unit pickup tines or crop-row pointer. On the actual harvester, it starts with the feedroll arrangement. John Deere has implemented a concept layout well proven on the 7000 Series.

Key characteristics are a set of front feedrolls where, when the header interface is in a vertical position; the upper-front feedroll (UFFR) reaches out about 60 mm (2.4 in) over the crop in front of the lower one, grabbing the mat from the harvesting header and pulling it into the feedroll gap. This is a key function when corn headers without feed augers are mounted; assuring the machine’s crop feeder is the sole length-of-cut (LOC) metering unit of the harvester.

On its way to the cutterhead, the radial-arc-feed roll arrangement applies pressure to the crop for superior cut quality. The crop mat is perfectly compressed until the last second before transitioning into the knives.

From the moment the knife pockets start unloading, the cutterhead band takes the crop particle stream, collecting it for launching into the crop chute.

The crop path follows a constant curve between the cutterhead floor and the accelerator entrance. The crop accelerator, the spout transition, and the spout build the machine’s crop discharge device. All components that have an acceleration impact on the crop perfectly integrate tangentially into this curve for a fully unobstructed crop flow.

With 1800 rpm, the accelerator provides sufficient thrust to the crop stream for loading with the largest of heads without consuming excessive power. Rather than being carried by the accelerator rotor, the crop follows the curve of the accelerator band before moving through the transition directly into the spout base, from where on it follows the spout contour.

The crop hits the transition front liner just below the spout entrance at a shallow angle, minimizing component wear and inertia losses. This constant flow curve was designed to the spout as gently as possible so that the crop flow components had the least friction effect on the crop particles.

Sufficient space on the vehicle for a cab that allows for more operator leg room, though keeping the overall machine compact, was a key demand.

Ultimately, the 8000 Series SPFHs provide superior crop-flow efficiency, resulting in industry-leading machine capacity in respective horsepower classes as well as low-specific-fuel consumption (amount of diesel per ton of crop harvested). Combined with Dura Line™ technology, the 8000 Series SPFH triggers the lowest possible machine maintenance with minimal cost of operation.

Crop accelerator

On its way to the trailer, the crop must be elevated more than 4 m (13 ft) high between the accelerator exit and the spout end. It must overcome a certain friction along the transition and spout liners until it is ejected off the spout end cap. When opening corn fields, producers can expect crop being airborne over a distance of 15 m to 20 m (50 ft to 65 ft) into the following trailer.

It is the task of the crop accelerator to provide sufficient thrust with appropriate efficiency to the crop particles to be loaded in all circumstances. An exactly specified air inlet in the accelerator housing assures a perfect spout crop jet when the kernel processor is installed.

Crop transition

The crop transition is completely lined with high-grade wear elements, which can easily be inspected and replaced from the machines service compartment through an access hatch. A unique manufacturing process allows even, customized hardening of the wear liners, perfectly addressing the individual wear situation in the cone. The transition is bearing the massive head gear-driven spout turning mechanism.

8000 Series SPFH features a spring-loaded cam-torque limiter inside the spout-turning drive mechanism. The spout hitting an obstacle is perfectly secured. However, the spout would never rotate uncontrolled and hit the cab. The spout turning sensor precisely monitors the spout position even when the spout clutch would have been triggered and mechanical end stops additionally secure the system.

|

|

Maximize animal performance through forage quality Maximize animal performance through forage quality

The unique Dura-Drum™ cutterhead design, together with the portfolio of cutterhead configurations, allows 8000 Series machine owners to perfectly specify their harvesters for meeting all operating demands. Three different cutterhead configurations with 10, 12, or 14 lines of knives, a full or half set of knives, and in conjunction with 1100 or 1200 cutterhead rpm provide an overall range of length of cut (LOC) from 3 mm (0.12 in.) up to 52 mm (2 in.). The 8000 Series Self-Propelled Forage Harvesters (SPFH) meet any customer requirements.

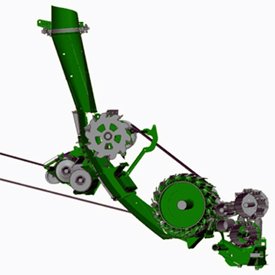

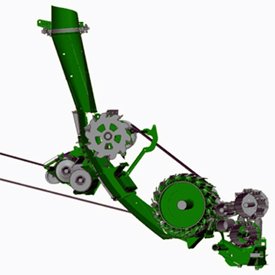

Kernel processor technology

ndustry-leading crop processing technology, such as from a conventional roller kernel processor, or from the latest XStream KP disk processing technology characterizes the 8000 Series approach to highest harvesting quality, essential for maximum performance.

8000 Series SPFH can be equipped with crop reprocessing technology, resulting in corn silage samples complying with highest-quality standards and kernel processor scores. Crop processing principles are implemented on the harvesters reflecting the various crop conditions as well as the harvesting capacity of the machines relative to their engine power.

In the 8100 and 8200 models, the John Deere Premium KP is installed in base.

On machines in the higher performance classes (8300 – 8600), the choice between the John Deere Premium KP and the John Deere XStream KP allows for tailoring a machine exactly to the needs and requests of dairy or feedlot producers. The metabolic speed of crops in meat production or ultra-high performing dairy cows or a biogas digester is essential, where the fermentation speed is the key to the economic success of the plant.

To address different crops and crop abrasiveness, different rolls can be selected. Furthermore, the speed differential can be altered, addressing the processing requirement relative to predominant crop maturity or moisture.

With the swing-in/swing-out concept, the kernel processor can be easily set to its working or storing position. The swing-in/swing-out is conveniently done in the machine service compartment. The processor swaps with a crop transition chute with just a few turns. In short-term alternating application, the processor can stay in its parking location. When it is not needed for a longer time, an optional articulating lifting beam with an electric hoist allows convenient removal from the machine.

|

|

Best-in-class power efficiency delivers unmatched performance in the field Best-in-class power efficiency delivers unmatched performance in the field

Unique machine layout maximizes power efficiency

Power-efficient crop handling and machine propulsion in the field are critical to maximum field performance on given engine power.

On the 8000 Series Self-Propelled Forage Harvester (SPFH), this is addressed through a unique machine layout leading to a fully harmonized crop path, avoiding any abrupt change of flow direction in the channel.

The 8000 Series machines feature automatic header detection, which automatically triggers all relevant calibrations and pre-settings memorized on the machine controllers.

Header lateral ground adaptation as well as a driveline synchronized with the machine crop feeder, or an optional dual header drive where the pickup tine reel would adapt the machine forward speed, and the feed auger speed would be in line with the feedroll speed, are leading to unobstructed crop entry into the harvester. Capacity and harvesting quality is maximized.

Advanced header control and active header guidance on corn heads allows precise header positioning through feelers, while the head is not in contact with the ground, resulting in an absolutely even stubble field.

Header attaching comfort is unmatched. Operations are reduced to manually applying the locking lever, and quick-coupling electric and hydraulic services.

|

|

ProDrive™ system coupled with large tires boost performance and uptime in soft conditions ProDrive™ system coupled with large tires boost performance and uptime in soft conditions

ProDrive is the industry-leading ground-drive propulsion.

Due to weather conditions, the harvesting window becomes shorter and in some areas around the globe, the machine has to work under very wet and soft soil conditions. This leads customers to get a forage harvester which can manage harvesting in these varying conditions.

The 8000 Series with ProDrive ground-drive propulsion, in conjunction with largest tires in the industry and optimized weight distribution, leads to maximum performance and uptime in soft soil conditions.

The largest tires, with a diameter of 1067 mm (42 in.) and a width of 900 mm (35.4 in.), deliver in comparison to a 7000 Series tires, a 34 percent larger footprint helps the 8000 Series with increased traction as well as less ground compaction.

The 8000 Series performs without compromises due to the industry-leading ground clearance, especially in soft soil conditions.

|

|

Total Care Total Care

Total Care overview

Total Care is an extended service program that allows customers to secure annual maintenance costs and be in a better position to prevent downtime during harvest. Total Care is available to customers purchasing a new 8000 or 9000 Series Self Propelled Forage Harvester. There are four plan offerings, Total Care Select, Total Care Ultimate, Total Care Select – Full Service, and Total Care Ultimate – Full Service. The Full Service plans indicate labor IS included while our original Total Care Select and Ultimate plans do not include labor. All Total Care plans are designed to help you maintain the original performance and uptime of your new machine.

Benefits

- Maximize machine performance and reliability through regular inspections and regularly scheduled maintenance

- Manage unforeseen financial risk and control operating expenses

- Replace worn parts as needed to ensure the customer does not experience downtime during the next use season

- In-season wear parts replacement (if needed) on both the traction unit and front-end equipment

Requirements and term lengths

Total Care Select

Total Care Select – Full Service |

PowerGard Comprehensive Requirement |

Dura Line Requirement |

| 3 years/1500 hours |

4 years/1500 hours |

Basic, Premium, or Ultimate |

| 3 years/2000 hours |

4 years/2500 hours |

Basic, Premium, or Ultimate |

| 3 years/2500 hours |

4 years/3000 hours |

Basic, Premium, or Ultimate |

| 3 years/3000 hours |

4 years/3500 hours |

Basic, Premium, or Ultimate |

Total Care Ultimate

Total Care Select – Full Service |

PowerGard Comprehensive Requirement |

Dura Line Requirement |

| 3 years/1500 hours |

4 years/1500 hours |

Ultimate |

| 3 years/2000 hours |

4 years/2500 hours |

Ultimate |

| 3 years/2500 hours |

4 years/3000 hours |

Ultimate |

| 3 years/3000 hours |

4 years/3500 hours |

Ultimate |

Plan details

Total Care Select

Total Care Select – Full Service |

Inspection Plan |

Maintenance Plan |

Wear Parts |

| 3 years/1500 hours |

Three inspections |

Three scheduled maintenance events |

Wear parts coverage allowance included |

| 3 years/2000 hours |

Four inspections |

Four scheduled maintenance events |

| 3 years/2500 hours |

Five inspections |

Five scheduled maintenance events |

| 3 years/3000 hours |

Six inspections |

Six scheduled maintenance events |

Total Care Ultimate

Total Care Select – Full Service |

Inspection Plan |

Maintenance Plan |

Wear Parts |

Additional Coverage |

| 3 years/1500 hours |

Three inspections |

Six scheduled maintenance events |

Wear parts coverage allowance included |

Additional wear parts replacement coverage and additional filter coverage

|

| 3 years/2000 hours |

Four inspections |

Eight scheduled maintenance events |

| 3 years/2500 hours |

Five inspections |

Ten scheduled maintenance events |

| 3 years/3000 hours |

Six inspections |

12 scheduled maintenance events |

Not included:

-

In-season maintenance

- Technician field travel and machine transport

- Insurance covered events

- Abuse and/or neglect

|

|

|

KEY SPECS

|

Key_Specs

| Maximum power |

430 kW

585 PS / 577 hp |

| Engine |

Type

PowerTech™ PSS 13.5L

Exhaust emission regulation compliancy - Final Tier 4 / Stage V

Displacement

13.5 L

823.8 cu in.

Model

Europe: 6135HZ021

North America: 6135HZ022

Cylinders

Inline 6 |

| Fuel system |

Unit injector plus four valves |

| Fuel tank capacity |

1,100 L

290.6 U.S. gal. |

| DEF tank capacity ( for FT4 or EU Stage V emission level) |

43 L

11.4 U.S. gal. |

|

|

ENGINE POWER

|

Engine_power

| Maximum power |

430 kW

585 PS / 577 hp |

| Fuel tank capacity |

1,100 L

290.6 U.S. gal. |

| DEF tank capacity ( for FT4 or EU Stage V emission level) |

43 L

11.4 U.S. gal. |

|

|

ENGINE

|

Engine

| Manufacturer |

John Deere |

| Type |

PowerTech™ PSS 13.5L

Exhaust emission regulation compliancy - Final Tier 4 / Stage V |

| Model |

Europe: 6135HZ021

North America: 6135HZ022 |

| Displacement |

13.5 L

823.8 cu in. |

| Cylinders |

In line six |

| Speed on road |

1400-2100 rpm |

| Engine/ground speed management |

Optional |

| Fuel system |

Unit injector plus four valves |

|

|

COOLING SYSTEM

|

Cooling_system

| Cooling system capacity |

113 L

29.85 U.S. gal. |

| Cooling fan drive |

Direct |

|

|

DRIVELINE

|

Driveline

| Ground drive |

Standard: Hydrostatic, 3-speed - manual shift with helical gears

Engine rpm on road: 1650 rpm

Optional: ProDrive™, autoshift transmission, differential lock (automatic and manual), automatic wet brake system

Engine rpm on road: 1400-2100 rpm |

| Hydraulics |

Load sensing |

| Crop harvesting unit |

Harvest channel standard |

| Crop flow components |

Low-friction crop-flow concept |

| Main clutch |

Dry clutch |

| Number of discs |

One disc |

| Main driveband |

Reinforced with Kevlar inserts |

| Belt tensioning |

Active, hydraulic pressure |

| Main driveband, polybelt belts |

Six ribs |

|

|

ELECTRICAL SYSTEM/ELECTRICAL AND HYDRAULIC SYSTEM

|

Electrical_system/Electrical_and_hydraulic_system

| Type/voltage |

13 V |

| Batteries/battery quantity/capacity |

2 x 174 amp-hr |

| Alternator |

200 amp |

| Hydraulic system capacity |

50 L

13.2 U.S. gal. |

|

|

GROUND DRIVE

|

Ground_drive

| Type |

Standard: hydrostatic, 3-speed manual shift

Optional: ProDrive, autoshift transmission |

| Differential lock |

Manual or automatic (optional comes with ProDrive) |

| Maximum transport speed |

Hydrostatic transmission: 25 / 30 km/h

15.5 / 18.6 mph

ProDrive transmission: 20 / 25 / 30 / 40 km/h

12.4 / 15.5 / 18.6 / 24.9 mph |

| Rear axle type |

Hydro-mechanical 4WD |

| Automatic wet brake system |

Available with ProDrive transmission |

| Engine speed management |

Optional |

|

|

CAB

|

Cab

| Tilt and extend steering column |

Standard |

| Air conditioning and heater |

Standard - ClimaTrak |

| Cool box |

Optional |

| Trainee seat |

Standard

Leather seat optional |

| Hectare counter |

Standard |

| Operator information system |

Cornerpost display

Armrest display (Touchscreen)

Side rail display (Touchscreen) optional |

| CAN bus electronics |

Standard |

| Operator's seat |

Air-suspension seat optional

Leather seat optional |

| Side window wiper |

Rear and side window wiper optional

Parallel-type windscreen wiper |

| Electric adjust and heated |

Optional on rear view mirrors |

| Rearview mirrors |

Standard |

|

|

MACHINE MANAGEMENT SOLUTIONS

|

Machine_management_solutions

| Yield monitoring |

Harvest Monitor™ optional |

| Documentation |

Harvest Doc™ optional |

| Crop analysis |

HarvestLab™ 3000 optional |

| Length-of-cut control based on crop parameter |

Infinitely variable length-of-cut (IVLOC™) standard

AutoLOC™ optional with HarvestLab 3000 |

| Assisted steering systems |

AutoTrac or Manual RowSense optional |

|

|

LENGTH OF CUT

|

Length_of_cut

| Range |

Range at 1100 rpm

40 knives: 7-26 mm (0.275-1.0 in.) LOC / 1 mm (0.04 in.) steps

48 knives: 6-22 mm (0.24-0.87 in.) LOC / 1 mm (0.04 in.) steps

56 knives: 5-19 mm (0.20-0.75 in.) LOC / 1 mm (0.04 in.) steps

Range at 1200 rpm

56 knives: 4-17 mm (0.16-0.67 in.) LOC / 1 mm (0.04 in.) steps

64 knives: 3-15 mm (0.12-0.59 in.) LOC / 1 mm (0.04 in.) steps |

|

|

FEEDING SYSTEM/FEEDROLLS

|

Feeding_system/Feedrolls

| Feed roll frame opening |

Swing away, 37-45 degree (angle) |

| Number |

Four |

| Metal detector |

Standard

Stone detector is optional |

| Width, front |

660 mm

26 in. |

| Standard feedroll drive |

Hydro feedroll drive IVLOC standard

Infinitely header drive speed standard |

|

|

CUTTERHEAD

|

Cutterhead

| Type |

Dura-Drum™ cutterhead |

| Cutterhead housing width |

686 mm

27 in. |

| Knife drum width |

680 mm

26.8 in. |

| Knife drum diameter |

670 mm

26.3 in. |

| Speed at rated engine speed |

Standard - 1100 rpm

Optional - 1200 rpm |

| Knife types available (crop) |

Straight - grass

Curved - corn |

| Number of knives |

40 - 48 - 56 - 64 |

| Shear bar, reversible |

Grass, corn, or Dura Line Plus |

| Shear bar adjust |

Fine shearbar adjust

Quick shearbar adjust |

|

|

KNIFE SHARPENING SYSTEM

|

Knife_sharpening_system

| Reverse rotation |

Yes |

| Automatic from cab |

Yes, remote from cab |

| Reverse drive |

Standard |

| Sharpening modes |

Grinding and finishing |

|

|

KERNEL PROCESSOR

|

Kernel_processor

| Type |

Premium KP (8100-8600)

XStream KP (8300-8600) |

| Quick-change |

Quick kernel processor - swing in/swing out |

| Quick KP removal |

Optional crane with remote-controlled electric hoist |

|

|

JOHN DEERE PREMIUM KP

|

John_Deere_Premium_KP

| Housing |

Standard KP housing |

| Lubrication |

Grease |

| Roll diameter |

240 mm

9.45 in. |

| Speed differential / Roll speed (lower) |

32 percent

Optional 40 percent |

| Sorghum, roll teeth number (speed differential) |

238 (32 percent) |

| Weight |

320 kg

145 lb |

| Available KP rolls |

Standard sawtooth

Duraline sawtooth

Whole crop |

|

|

BLOWER/CROP ACCELERATOR

|

Blower/Crop_accelerator

| Rotor diameter/housing width |

Rotor diameter: 560 mm

22.86 in.

Housing width: 540 mm

21.26 in. |

| Number of blades |

10 |

| Speed (option) |

1800 rpm |

|

|

SPOUT

|

Spout

| Rotation, degrees |

210 degree (angle) |

| Hydraulic height position |

Hydraulic raise and lower standard

Automatic spout positioning optional |

| Double-cap deflection |

Standard |

|

|

MAINTENANCE

|

Maintenance

| Rotary radiator screen cleaner |

Standard |

| Automatic lubrication system |

Optional |

| Engine oil and filter change duration |

Plus-50™ II oil: 500 hours

Other oil: 250 hours |

|

|

VEHICLE

|

Vehicle

| With front tires |

710/70R42 |

| With rear tires |

620/60R30 |

| Transport length (without header) |

6.6 m

21.7 ft |

| Transport width (without header) |

3-3.7 m

9.84-12.1 ft |

| Transport height (to cab roof) |

3.89 m

12.75 ft |

| Working height (maximum) |

Height to spout: 6.60 m

21.65 ft |

|

|

PROPELLING DRIVE

|

Propelling_drive

| Standard |

Hydrostatic, 3-speed - manual shift with helical gears |

|

|

TRANSMISSION

|

Transmission

| Type |

Standard: Hydrostatic, 3-speed - manual shift with helical gears

Hydro-mechanical 4WD rear axle optional |

|

|

LITERATURE

|

Literature

Name

|

Link

|

| View Product Brochure |

Download |

|

Advanced comfort and serviceability improve performance and uptime

Advanced comfort and serviceability improve performance and uptime Heavier designed components increase reliability while improving uptime and lowering cost of operation

Heavier designed components increase reliability while improving uptime and lowering cost of operation Optimal design and positioning of components increases crop delivery performance

Optimal design and positioning of components increases crop delivery performance Maximize animal performance through forage quality

Maximize animal performance through forage quality Best-in-class power efficiency delivers unmatched performance in the field

Best-in-class power efficiency delivers unmatched performance in the field

ProDrive™ system coupled with large tires boost performance and uptime in soft conditions

ProDrive™ system coupled with large tires boost performance and uptime in soft conditions Total Care

Total Care