|

Fast-turning saw blades cut all kinds of crop Fast-turning saw blades cut all kinds of crop

The saw blades of John Deere rotary crop headers cut quickly and thoroughly at a high speed of rotation. As the fast-turning blades cut the full width, crops can be harvested regardless of the row spacing. Thanks to this row-independent harvesting technology, the field can be worked from any side, which is particularly important for down crop.

The fast-turning saw blades allow crops with a lot of weeds to be harvested easily. Besides maize, a wide range of crops such as sorghum, whole crop silage, oilseed, canola, pampas grass, and miscanthus can be harvested.

Key features:

- Fast turning saw blades can cut in difficult harvesting conditions to give the operator increased uptime.

- Headers can be used in various stemmed crops and there is no need for extra headers, which saves on the cost of operation.

|

|

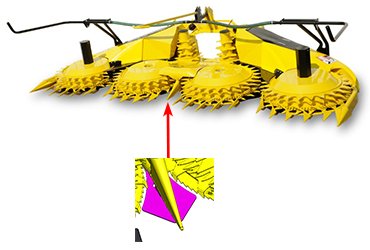

Intake fingers and gatherer drums for secure crop guidance Intake fingers and gatherer drums for secure crop guidance

After the fast-rotating blades cut the crop, the intake fingers push the plants into the gatherer drums that rotate in the same direction at low speeds. Every plant is pushed into the teeth of the gatherer drum. The specially designed shape of the teeth ensures that both small and large plants are conveyed in a secure way.

In the machine, the plants are taken off the back of the gatherer drum by scrapers. Depending on the width of the header, they are forwarded to the cross-feed drums or immediately fed into the angled feed drums in the middle of the machine.

Key feature:

- Every plant is individually and securely pushed into the gatherer drum (Performance).

|

|

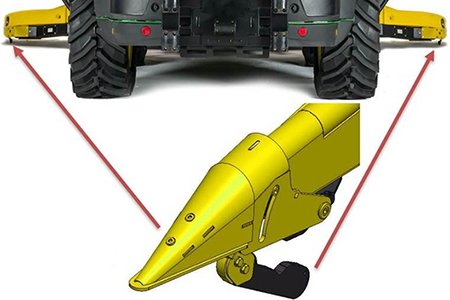

Advanced Header Control (AHC) sensors Advanced Header Control (AHC) sensors

The AHC sensors are located at the two outermost points from the header. The sensors continuously scan the ground and adjust the height and inclination of the attachment. This quick adjustment guarantees a constant stubble height.

The AHC sensors are optional equipment for eight- and 10-row machines.

The AHC sensors are base equipment for 12-row machines.

|

|

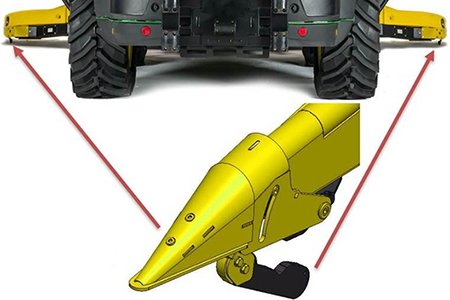

Third header height sensor Third header height sensor

For eight- and 10-row machines, the third sensor is optional equipment. The third sensor is only available in combination with the RowSense™ system as it is installed in the central RowSense pointer.

The two-sensor Advanced Header Control (AHC) does a good job in most conditions. The optional third sensor is needed in extremely uneven terrain or on wide headers.

|

Fast-turning saw blades cut all kinds of crop

Fast-turning saw blades cut all kinds of crop

Intake fingers and gatherer drums for secure crop guidance

Intake fingers and gatherer drums for secure crop guidance Lengthwise feeding for optimal chopping quality

Lengthwise feeding for optimal chopping quality Deflectors guide the plants to the rotors

Deflectors guide the plants to the rotors Advanced Header Control (AHC) sensors

Advanced Header Control (AHC) sensors Third header height sensor

Third header height sensor