|

Increase overall productivity with Central Commodity System (CCS™) seed delivery system Increase overall productivity with Central Commodity System (CCS™) seed delivery system

CCS seed delivery adds productivity through:

- Increased seed capacity

- Bulk fill capability

- Easy, thorough cleanout

Crops that can be planted with the CCS System include corn, sweet corn, popcorn, cotton, sunflowers, sugar beets, soybeans, and sorghum (milo).

Filling the tanks is convenient due to a central filling location. The staircase and railing provide access to the filling platform between the tanks. Additionally, each tank has an adjustable bin-level sensor to alert the operator when it is time to fill.

A light-emitting diode (LED) fill light package is included on machines equipped with CCS. This feature includes two LED lights conveniently mounted on the railings of the machine. The lights are turned on and off with their own switch located at the bottom of the staircase.

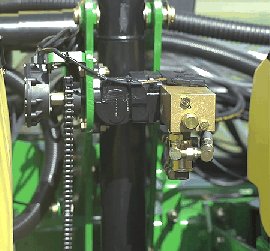

If the seed-carrying vehicle requires hydraulic power to run the unloading system, the auxiliary hydraulic coupler option is available. These couplers are located at the bottom of the staircase and can be coupled under pressure. The system has a separate system filter that ensures the planter hydraulic system remains free of contaminants.

CCS system capacities by model:

|

Model

|

Without liquid tank

|

With liquid tank

|

|

1725C 12R30

|

1938 L (55 bu)

|

---

|

|

1725C 12Row36/38

|

1938 L (55 bu)

|

---

|

|

1725C 12Row38/40

|

1938 L (55 bu)

|

---

|

|

1725C 16R30

|

1938 L (55 bu)

|

---

|

|

DB60T

|

4757 L (135 bu)

|

---

|

|

DR12

|

Optional

|

---

|

|

DR16

|

Optional

|

---

|

|

DR18

|

Optional

|

---

|

|

DR24

|

Optional

|

---

|

|

DR12T

|

Optional

|

---

|

|

1775NT 12Row30

|

3524 L (100 bu)

|

3524 L (100 bu)

|

|

1775NT 16Row30

|

4581 L (130 bu)

|

4581 L (130 bu)

|

|

1795 23Row15

|

3524 L (100 bu)

|

2467 L (70 bu)

|

|

1795 24Row15

|

3524 L (100 bu)

|

2467 L (70 bu)

|

|

1795 24Row20

|

4581 L (130 bu)

|

3524 L (100 bu)

|

|

1795 31Row15

|

4581 L (130 bu)

|

3524 L (100 bu)

|

|

1795 32Row15

|

4581 L (130 bu)

|

3524 L (100 bu)

|

|

DB44 24Row22

|

4581 L (130 bu)

|

4581 L (130 bu)

|

|

DB60 24Row30

|

4581 L (130 bu)

|

4581 L (130 bu)

|

|

DB60 24Row30/47Row15

|

4581 L (130 bu)

|

4581 L (130 bu)

|

|

DB60 24Row30/48Row15

|

4581 L (130 bu)

|

4581 L (130 bu)

|

|

DB60 36Row20

|

4581 L (130 bu)

|

4581 L (130 bu)

|

|

DB66 36Row22

|

4581 L (130 bu)

|

4581 L (130 bu)

|

|

DB80 32Row30

|

4581 L (130 bu)

|

4581 L (130 bu)

|

|

DB80 48Row20

|

4581 L (130 bu)

|

4581 L (130 bu)

|

|

DB88 48Row22

|

4581 L (130 bu)

|

4581 L (130 bu)

|

|

DB90 36Row30

|

4581 L (130 bu)

|

4581 L (130 bu)

|

|

DB90 54Row20

|

4581 L (130 bu)

|

4581 L (130 bu)

|

|

DB120 48Row30

|

4757 L (135 bu)

|

4757 L (135 bu)

|

|

DB37 16Row70/24Row45cm

|

2467 L (70 bu)

|

2467 L (70 bu)

|

|

DB37 16Row70cm

|

2467 L (70 bu)

|

2467 L (70 bu)

|

|

DB55 24Row70cm

|

3524 L (100 bu)

|

3524 L (100 bu)

|

|

DB55 36Row45cm/70cm

|

3524 L (100 bu)

|

3524 L (100 bu)

|

|

DB74 32Row70cm

|

3524 L (100 bu)

|

3524 L (100 bu)

|

|

DB83 36Row70cm

|

3524 L (100 bu)

|

3524 L (100 bu)

|

|

DB41 24Row52.5/33Row38cm

|

4581 L (130 bu)

|

4581 L (130 bu)

|

|

DB41 24Row52.5cm

|

4581 L (130 bu)

|

4581 L (130 bu)

|

|

DB62 36Row52.5cm

|

4581 L (130 bu)

|

4581 L (130 bu)

|

|

DB83 48Row52.5cm

|

4581 L (130 bu)

|

4581 L (130 bu)

|

NOTE: CCS system capacity on 1795 machines are reduced when a fertilizer tank is equipped.

NOTE: DB60T and DB120 machines use two 1762-L (50-bu) tanks and one 1233-L (35-bu) tank.

Seed delivery process

CCS is about reducing the time spent filling the planter with seed while maximizing the time spent planting. CCS for planters is a form of seed handling and delivery. The row-units perform the final task of seed metering and placement.

The CCS seed delivery process relies on a hydraulically driven fan to move seed from the CCS tanks to the row-unit hoppers. A flow control valve and gauge, located near the tank, allows for the proper tank pressure setting based on seed type. For normal operation, the CCS functions of fan and agitator control, as well as bin level sensing alerts, are controlled by status of the height switch. The CCS functions are enabled when the machine is lowered and disabled when the machine is raised. In addition, the CCS functions can be engaged for CCS hose cleanout using the switch on the back of the planter when oil flow is present. On models with software-based CCS control, CCS functions can be enabled or disabled through software interface in the cab as well as the switch on the back of the planter.

Air from the fan pressurizes the CCS tanks and delivers seed to the seed hoppers. Airflow enters the seed tanks through a nozzle in the manifold which pressurizes the tank. The air then picks up seed and moves it out the other end of the nozzle into seed delivery hoses. These hoses route the seed toward the hopper. A small amount of seed is traveling in the delivery hoses only when needed.

The hopper fills with seed until the delivery hose (discharge elbow) is covered. Once the opening is restricted, seed flow through the hose stops. Air flowing to the row-unit travels into the hopper and is the source of air for the vacuum system. This provides a much cleaner air source than previous meter designs. As the seed is picked up by the meter and planted, the seed pool shrinks until the end of the delivery hose is uncovered. At that time, the airflow and seed delivery resume and the seed pool in the hopper is replenished.

CCS tank scales for DB Planter models

The CCS tank scales for DB models are a stand-alone system from Digi-Star. Load cells are installed at the factory and can be ordered for CCS equipped machines.

There are three load cells: two at the rear of the CCS cradle and one at the front. They weigh both tanks as one; individual tank weights cannot be determined.

The load cells and display are made by Digi-Star. They are not on the controller area network (CAN) bus system so they are not integrated into SeedStar™ software in any way. The monitor is sold separately through Digi-Star.

CCS seed cleanout

Seed cleanout could is easy with a CCS planter. When finished planting, any remaining seed can simply be removed via access doors at the bottom of the CCS tank.

CCS seed delivery hoses are then purged with air from the CCS fan, and the excess seed is pushed to the individual meters. The vacuum meter door is opened and seed is removed with the supplied catch pan.

|

Advance with MaxEmerge™ 5 advantages

Advance with MaxEmerge™ 5 advantages Increase overall productivity with Central Commodity System (CCS™) seed delivery system

Increase overall productivity with Central Commodity System (CCS™) seed delivery system Seed variable-rate drive

Seed variable-rate drive

Lift-assist wheel steering

Lift-assist wheel steering John Deere Connected Support™ prevents downtime and efficiently resolves issues with revolutionary technology-based solutions

John Deere Connected Support™ prevents downtime and efficiently resolves issues with revolutionary technology-based solutions