Features

|

Easily operate in tall crop with high-clearance design Easily operate in tall crop with high-clearance design

Perform detasseling in tall varieties of seed corn with 195.6 cm (77in.) of underframe clearance on the Hagie™ 204SP Detasseler.

- High underframe clearance allows you to operate in taller crop without damaging the plant tissue.

Hagie is a trademark of Hagie Manufacturing Company and similar to John Deere branded equipment, John Deere will also support Hagie equipment.

|

|

Match any crop height with adjustable automatic height control Match any crop height with adjustable automatic height control

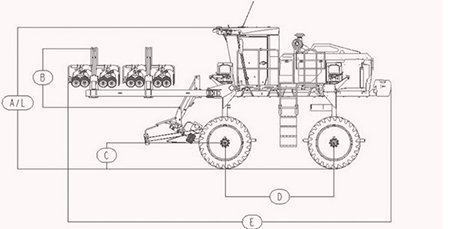

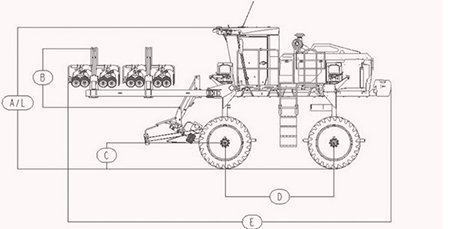

Experience a wide range of detasseling heights with a 167.6-cm (66-in.) lift arm range. The lift arm feature provides adjustments with the upper and lower position for detasseling capability that ranges from 0.63 m up to 2.5 m (2 ft up to 8.4 ft) above ground.

(B) Lift arm range of 167.6 cm (66 in.)

Hagie is a trademark of Hagie Manufacturing Company and similar to John Deere branded equipment, John Deere will also support Hagie equipment.

|

|

Enter the field any day with a lightweight design Enter the field any day with a lightweight design

Timing is critical when it comes to detasseling. The 6965.8-kg (15,357-lb) Hagie™ 204SP Detasseler features a lightweight design, allowing you to enter the field any day to perform your detasseling needs.

Hagie is a trademark of Hagie Manufacturing Company and similar to John Deere branded equipment, John Deere will also support Hagie equipment.

|

|

Improve operations and comfort with active air suspension Improve operations and comfort with active air suspension

The Hagie™ 204SP Detasseler features active air suspension.

Maximize operator comfort and improve operational functions of the detasseler attachments with the active air suspension on the Hagie 204SP Detasseler. In the field or on the road, active air suspension makes for a remarkably smooth ride.

An electric air compressor and air bag linkage enhances the air-ride suspension by making sure there is always the right amount of air in the suspension bags, from roading to operating in different field conditions.

Hagie is a trademark of Hagie Manufacturing Company, LLC and similar to John Deere branded equipment, John Deere will also support Hagie equipment.

|

|

QuickTach heads allow a quick and easy change between cutters and quad pullers QuickTach heads allow a quick and easy change between cutters and quad pullers

No tools are needed to quickly change from cutting to pulling attachments with just two locking pins on each head.

- Increase productivity by easily converting from cutting to pulling attachments

- No tools required to change from cutters to pullers

- Hydraulic quick connect couplers on the head attachments also increase the ease of changeover from cutters to pullers.

|

|

Focus more on detasseling and less on steering with AutoTrac™ RowSense™ Focus more on detasseling and less on steering with AutoTrac™ RowSense™

John Deere AutoTrac RowSense gives the Hagie 204SP detasseler the ability to steer itself. The result? Reduce operator fatigue and the ability to relax and focus more on the quality of detasseling job the machine is doing. With the G5 Universal Display, StarFire™ 7500 antenna, AutoTrac Universal 300, and RowSense feelers, the Hagie 204SP Detasseler is ready to AutoTrac through the field in the long hours of detasseling season.

Benefits

- Less strain on the operator

- Hands free operation

- Less crop damage

- Reduce fatigue

|

|

New level of operator comfort with the John Deere cab features New level of operator comfort with the John Deere cab features

The Hagie detasseler comes with a cab that offers a comfortable and quiet working environment with plenty of visibility, space, and features. For those long hours required during the detasseling season, the John Deere cab new to the Hagie 204SP provides improved operator comfort to reduce fatigue in the field. The cab features a Hagie designed side console that still provides simple detasseling controls.

Cab features

- Rear window tint

- Improved visibility

- Operator’s seat with air suspension

- Folding instructor seat

- AM/FM radio with Bluetooth® wireless functionality

- Tilt steering column

- Two 12-V power outlets

- Sun visor

- Halogen lights

- Hagie side console

Operators can easily adjust features and controls in the 204SP Detasseler operator’s station to maximize comfort and keep the machine performing throughout the field.

Bluetooth is a trademark of Bluetooth SIG, Inc.

|

|

Montag® 2108 Cover Crop System for Hagie™ 204SP Detasselers Montag® 2108 Cover Crop System for Hagie™ 204SP Detasselers

Boost the versatility of the Hagie 204SP Detasseler and optimize soil health with a cover crop seeding solution. The Montag 2108 Cover Crop System is an engineered solution specifically designed to be compatible with model year 2015 to 2024 Hagie 204SP Detasselers.

- Increases uptime and asset utilization, to reduce the cost of operation via single pass to apply nutrients and/or cover crop seed at the same time as male row destroying or as stand-alone seeding option

- Improve soil health, reduced soil erosion, and water quality improvements from the use of cover crop practices

Hagie is a trademark of Hagie Manufacturing Company and similar to John Deere branded equipment, John Deere will also support Hagie equipment.

The Montag cover crop system features the Gen 2 2108 single bin design totaling 1-m3 (35-cu ft) capacity, sized to fit the operation. The system is controlled with Montag MTC200 controller for a simple, user-friendly operator interface.

- Available as stand-alone seeding option

- Configurable with up to eight primary meters - flexible base able to meet multiple application requirements for 12 (9.1 m [30 ft]) to 15 (11.43 m [37.5ft]) rows

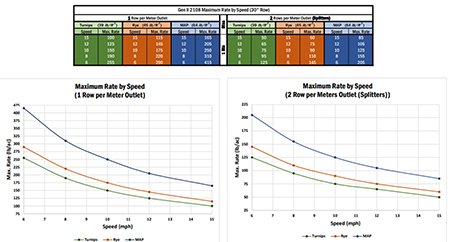

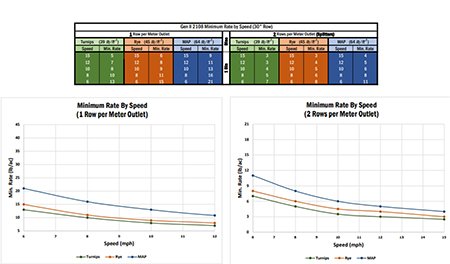

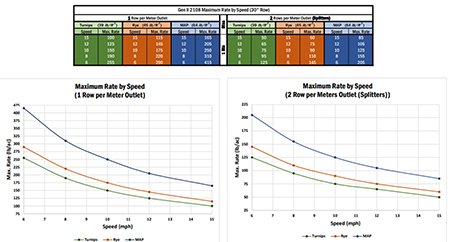

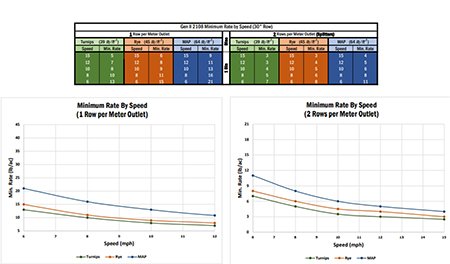

Montag chart

When performing seeding applications at 16.1 km/h (10 mph), producers can apply 2.3 kg (5 lb) to 40.8 kg (90 lb) of seed per acre to meet individual productivity needs (see the rate charts above for more details). The Montag 2108 Cover Crop System provides a unique solution to protect and nurture soil health while enhancing versatility, making the Hagie 204SP Detasseler a one-machine solution for late season needs.

| Key specifications |

| Row configurable |

12 (9.1 m [30 ft]) to 15 (11.43 m [37.5ft]) |

| Section sonfigurable |

1-4 sections |

| Slide gate control |

Manual lever |

| Controller |

Montag MTC200 controller |

| Product capacity (bin) |

0.85 m3 (30-cu ft) bin: 0.99 m3 (34.8-cu ft), 1.11 ton* (2447.13 lb) |

| Rate capacity (bin) |

See 2108 rate chart at www.montagmfg.com |

| 2108 weight** |

385.55 kg (850 lb) to 453.6 kg (1,000 lb) |

| Fill height |

3.6 m (12 ft) |

| Product fill inlet size |

0.97 m (3.2 ft) |

| Product outlet hose size |

5.08 cm (2 in.) |

| Required hydraulic capacity |

52.99 L/min (14 gpm) |

| Required hydraulic pressure |

137.89 bar (2000 psi) |

*Calculated using 1.025 kg/L (64 lb/cu ft) product density

**Unloaded, dry weight (approximated). Excludes platform and mounting kit

NOTE: Montag Manufacturing has an allied partnership agreement with John Deere as it relates to the cover crop system and is responsible for providing sales and technical support to dealers.

For additional information about the system, visit www.montagmfg.com or call 712-852-4572. Montag is a trademark of Montag Manufacturing, Inc.

|

|

Improve application accuracy with the AB30 Air Boom Improve application accuracy with the AB30 Air Boom

For ag service providers and large-scale producers, the AB30 Air Boom is available as an option for the 800R Floater. The AB30 Air Boom builds on the advantages of the 800R chassis with the addition of an 8.5-m3 (300-cu ft) dry box with dual-product capability and a 21.3-m (70-ft) wide boom.

Durability and uptime are extremely important to an ag retailer’s business. With the number of acres these machines need to cover each year and the varying weather conditions that can impact the schedule, increasing uptime is crucial to the profitability and success of the ag retailer. The AB30 Air Boom is designed to maximize uptime through improved performance, reliability, and operator comfort.

Performance

The air boom option allows operators to accurately apply dry fertilizer across a wide 21.3-m (70-ft) swath at speeds up to 48.3 km/h (30 mph), and at maximum rates up to 544.3 kg (1,200 lb) per acre at 16.1 km/h (10 mph). With its 8.5-m3 (300-cu ft) capacity dry box and dual-bin configuration, operators can simultaneously apply up to two products at variable rates to better meet crop nutrient needs with fewer passes over the field. Application accuracy is further improved with half-width section control.

The air distribution system features an efficient design that consistently delivers even air flow from the fan to the booms. The closed-loop speed control allows the fan to run independent of the motor speed, increasing efficiency. This design requires less power for the air system and diverts more engine power to the ground during acceleration and operation.

Reliability

The electrical and hydraulic systems have been designed from the ground up with full integration into the 4600 CommandCenter™ Display for easier control and maintenance. The boom structure and supports have also been strengthened to extend the life of the booms regardless of the terrain.

To improve the reliability of the air distribution system, the fan oil cooler is mounted on the right side of the machine, exposing it to less dust and vibration while making it easier to maintain. A large screen was also added over the fan air intake to block residue and debris from entering the air system.

Operator comfort

The front ladder provides easy access to the machine even when the booms are folded. During tendering, operators can quickly access the top of the dry box from the cab platform. Handrails can then be folded up on both sides of the dry box, allowing the operator to work more efficiently.

The 800R with the AB30 Air Boom improves the revenue potential for ag service providers by increasing machine productivity through greater durability and superior field performance.

|

|

Maximize seasonal capabilities with the LS20 Liquid System Maximize seasonal capabilities with the LS20 Liquid System

Seasonal flexibility is crucial for maximum machine utilization. LS20 Liquid System option maximizes the seasonal capabilities of the 800R. Together with Hagie™ Manufacturing, this liquid system is designed as a complete package with industry-leading advantages. Learn more on the LS20 product page.

Accurately apply low-rate herbicide and high-rate fertilizer with a single machine

During the busy spring season, you need to complete jobs as crops are planted, from applying high-rate fertilizer on unplanted corn fields to low-rate pre-emergent herbicide on soybeans. Dual centrifugal solution pumps with dedicated magnetic flow meters work together to achieve pin-point rate accuracy through the entire flow range between 18.9 and 1457.4 L/min (5 and 385 gpm).

Fast, clean, automated tank filling enabled by PowrSpray™ technology

When the tank is empty, every second counts trying to get back into the field. PowrSpray features independent fill and spray circuits with dedicated pumps to maximize flow. The dedicated self-priming transfer pump can fill the solution tank at over 1135.6 L/min (300 gpm).

This PowrSpray system can:

- Automatically fill to a predefined tank level while automatically adjusting engine speed

- Pull fresh water from the rinse tank to clean the fill system

- Be manually reduced if a slower fill rate is desired

- Pause filling, giving you sufficient time to add ingredients and rinse containers

- Allow for quick and easy operation at the load station for all skill levels

Cover more acres per pass using the widest factory-installed boom

The time-proven 27.4-m (90-ft) sprayer steel boom unlocks reliable productivity for ag service providers. This durable boom features:

- Full-boom breakaway

- Tridirectional boom tip breakaway

- Auto-fold

The standard dual plumbing system features 76.2-cm (30-in.) off-center high-flow nozzle bodies (turrets) and a 152.4-cm (60-in.) on-center cam-lock. When configured for 152.4-cm (60-in.) cam-lock spacing, the effective spray pattern is 29 m (95 ft). The 76.2-cm (30-in.) nozzle body configuration achieves a 27.4-m (90-ft) spray pattern.

|

|

John Deere Connected Support™ prevents downtime and efficiently resolves issues with revolutionary technology-based solutions John Deere Connected Support™ prevents downtime and efficiently resolves issues with revolutionary technology-based solutions

When you buy John Deere equipment, you expect reliability. You also know that problems can happen, and a product is only as good as the support behind it. That’s why John Deere equipment is prepared with technology that senses potential issues and can alert you and your dealer promptly—in the cab or anywhere you are.

John Deere Connected Support is a revolutionary change to support that leverages technology and the connectivity of JDLink™ telematics to prevent downtime and resolve problems faster. These tools decrease downtime by an average of 20 percent, enabling faster responses to unexpected problems and reducing technician trips to your machine. For some issues, unplanned downtime can even be prevented altogether through prediction of the issue.

With your permission, John Deere Connected Support:

- Keeps you running by monitoring machine health and promptly alerting you and your dealer of issues

- Saves time by remotely viewing in-cab displays, reducing trips to the machine

- Reduces or even eliminates technician trips to a machine through remote diagnostic and remote software reprogramming capabilities

- Connects experts with the information needed to respond to downtime faster and prevent it altogether

With more than a decade of experience leveraging connectivity to solve problems, no one else has the experience, tools, and knowledge to keep you running as John Deere and your John Deere dealer can. Connected Support is an in-base feature on all John Deere products with factory- or field-installed JDLink.

|

|

Easily operate in tall crop with high-clearance design

Easily operate in tall crop with high-clearance design Match any crop height with adjustable automatic height control

Match any crop height with adjustable automatic height control

Enter the field any day with a lightweight design

Enter the field any day with a lightweight design

Improve operations and comfort with active air suspension

Improve operations and comfort with active air suspension

QuickTach heads allow a quick and easy change between cutters and quad pullers

QuickTach heads allow a quick and easy change between cutters and quad pullers

Focus more on detasseling and less on steering with AutoTrac™ RowSense™

Focus more on detasseling and less on steering with AutoTrac™ RowSense™

New level of operator comfort with the John Deere cab features

New level of operator comfort with the John Deere cab features

Montag® 2108 Cover Crop System for Hagie™ 204SP Detasselers

Montag® 2108 Cover Crop System for Hagie™ 204SP Detasselers

Improve application accuracy with the AB30 Air Boom

Improve application accuracy with the AB30 Air Boom Maximize seasonal capabilities with the LS20 Liquid System

Maximize seasonal capabilities with the LS20 Liquid System John Deere Connected Support™ prevents downtime and efficiently resolves issues with revolutionary technology-based solutions

John Deere Connected Support™ prevents downtime and efficiently resolves issues with revolutionary technology-based solutions