- Monday 8:00AM - 5:00PM

- Tuesday 8:00AM - 5:00PM

- Wednesday 8:00AM - 5:00PM

- Thursday 8:00AM - 5:00PM

- Friday 8:00AM - 5:00PM

- Saturday Closed

- Sunday Closed

2025 John Deere C350 Mower-Conditioner

|

|

Achieving the right conditioning action can significantly reduce dry down time. That means less time needed to cure, maintaining optimum feed values, and preventing leaf loss in legumes. Hay and forage producers have a wide variety of crops and conditions. That’s why John Deere mower-conditioners offer four different conditioners.

Conditioner types include:

|

|

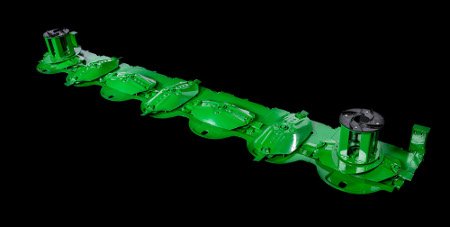

John Deere's patented design cutterbar is made from individual, diagonal-cut modules, making serviceability easy. Each module can be removed for service individually, leaving the remaining cutterbar modules attached to the frame.

Each cutting disk is attached to a shear hub (driver) on the splined pinion gear. Power to the disk is interrupted when the driver shears to protect the internal components of the cutterbar. Damage is limited to exposed components and does not require disassembly of the cutting modules.

The gauge shoe setting determines the height of the crop stubble, but also prevents the majority of the cutterbar from being in constant contact with abrasive soils and rocks. The S250, S300, S350, C300, C350, and C400 have three height adjustments on the gauge shoe. The C450 and C500 come from the factory with six adjustments. Through service attachments, gauge shoe extensions are available to increase the number of adjustments if there is a need for higher stubble height. |

|

Having sharp knives on your machine is critical to harvesting all your crop and leaving a clean-cut field. Changing dull or bent knives is no longer a time-consuming job with the John Deere quick-change knife (QCK) system. There are no worries about having an impact or air compressor to change out the bolts. Simply insert the QCK tool into the disk and press down. The knives can be swapped out in seconds.

|

|

An advantage John Deere has over most competitors is that the mower-conditioners transport directly behind the tractor at nearly the same width as its cut. Operators can transition from road to field configuration and back again quickly and easily.

Side-pull models (S250, S300, and S350) have the tongue positioned in the center of the frame and drivelines that enter from the top to improve transport width. |

|

Windrow formation is the final step of mower-conditioner functionality. Proper windrow formation is critical to reducing dry down times for dry hay and haylage or providing consistent chopping speeds and cut lengths for forage harvesting applications. Characteristics of a quality windrow include:

Sized to the width of the harvesting equipment or spread wide to allow for maximum exposure

John Deere mower-conditioners allow you to customize windrows to match your needs.

Adjustable swath boards help direct crop coming through the conditioner assembly, providing a quick adjustment to windrow width.

0 Series Mower-Conditioners come standard with forming vanes on the swath board when available. Previously referred to as a wide swath kit, the forming vanes allow the mower-conditioner to increase windrow widths up to 25 percent and can be used to further customize windrow formation to match crop conditions.

Forming shields allow fine-tuning of the windrow width. This can allow you to easily match the windrow to your tractor’s tire spacing and prevent driving on cut and conditioned crop.

|

| PTO speed | 1000 rpm |

|---|---|

| 1000 rpm 1-3/8 in. PTO | 90-150 hp 68-112 kW |

| Standard hitch | Equal angle |

| Optional hitch | Rockshaft swivel or Drawbar swivel |

| Hydraulic pressure required | 13,790 kPa 2,000 psi |

| Cutterbar - cutting width | 3.5 m 11.5 ft |

| Number of disks/knifes | 7 14 |

| Transport width | 3.5 m 11.5 ft |

| Tractor connection | 21 spline |

|---|---|

| Standard hitch | Equal angle |

| Optional hitch | Rockshaft swivel or Drawbar swivel |

| Hydraulic pressure required | 13,790 kPa 2,000 psi |

| Width | 236 cm 92.7 in. |

|---|---|

| Diameter | 60 cm 23.5 in. |

| Tines type | V-tines |

| Number of tines | 57 |

| Number of speeds | Two |

| Drive | 3-V powerband belt and sheaves |

| Width | 236 cm 92.7 in. |

|---|---|

| Diameter | 25.4 cm 10 in. |

| Type of material | Urethane or steel |

| Design | Urethane: Recessed cleat, Steel: Intermeshing flutes V-10 |

| Speed | 664 rpm |

| Drive | Telescoping shaft |

| Transport width | 3.5 m 11.5 ft |

|---|---|

| Transport length | 6.3 m 20.6 ft |

| Weight, roll conditioner | Swivel 2,978 kg 6,565 lb |

| Weight, impeller conditioner | With Equal angle 2,479 kg 5,465 lb Swivel 2,762 kg 6,089 lb With Urethane roll conditioner: 2,633 kg 5,805 lb Swivel 2,916 kg 6,429 lb With Steel roll conditioner: Equal angle 2,695 kg 5,941 lb |

| Standard tires | 11L-15 standard 11L-15, Optional: 31x13.5L 15 |

| Date collected | August 24, 2020 |

|---|

Name |

Link |

| View Product Brochure | Download |

Protect your crop with conditioner options to fit your needs

Protect your crop with conditioner options to fit your needs Reduced maintenance and proven cutterbar reliability with 5-year coverage

Reduced maintenance and proven cutterbar reliability with 5-year coverage Save time with quick-change knives

Save time with quick-change knives Quickly prepare the mower-conditioner for transport

Quickly prepare the mower-conditioner for transport Minimize dry down time with proper windrow formation

Minimize dry down time with proper windrow formation