Cyclonic V-twin engine is smooth running and powerful

Cyclonic V-twin engine is smooth running and powerful |

42-in. (107-cm) Accel Deep™ (42A) Mower Deck cuts clean and is versatile

42-in. (107-cm) Accel Deep™ (42A) Mower Deck cuts clean and is versatile

The 42-in. (107-cm) Accel Deep Mower Deck is a stamped-steel, deep, flat-top design that delivers excellent cut quality, productivity, cleanliness, durability, and versatility. Optimal performance and dispersion of clippings is provided, even at faster mowing speeds or in tall grass: - 4.97-in. (12.6-cm) depth throughout the entire deck shell for optimum mowing, mulching, and bagging performance

- Optional MulchControl™ system provides superior mulching performance and versatility

- Stamped-steel design eliminates sharp edges and corners where material can build up and diminish mowing performance

- Mower deck suspended from the vehicle for a smooth and level cut

- Adjustable mower wheels, positioned just above ground level, help reduce scalping

- 0.25-in. (6.4-mm) cut-height increments allow the mower to be set at the desired cut height

- Compatible with efficient 6.5-bu (229-L) two-bag material collection system

- Reducing the amount of recutting enables more power to be used to cut incoming grass, which greatly improves mower capacity.

- Helps maintain excellent cut quality at faster mowing speeds

- Clean flow of material out of discharge area prevents cut material from interfering with cutting the incoming grass, making it possible for the blades to cut incoming material cleanly.

- Even in mulching mode, cut evenness is improved compared to other designs because the additional depth allows for continuous circulation, optimal recutting, and an even distribution of clippings.

-

PRODUCTIVITY - GETS THE JOB DONE FAST

Deep mower-deck stamping gives high productivity, which gets the job done fast. It allows the cut and suspended material room to exit the deck quickly, reducing the amount of recutting so more power is available to process incoming grass: - Greatly improves mowers capacity to maintain excellent mowing performance in difficult mowing conditions and at higher speeds

-

Large discharge opening is both high and wide to handle more material: - Gives a smooth, even discharge of clippings at all mowing speeds

- Reduces the chance of plugging, especially important when operating in wet, thick, or dense grass and when bagging

- Cut-and-throw chute has a large, optimized inlet which aids in collecting material by using airflow from the large deck opening

- There are few places to catch and hold material on top and underneath the deck.

- Top of deck stays cleaner, reducing time and effort needed for cleaning and service

- Underside of deck is self-cleaning to maintain optimum performance without buildup of material to interfere with the flow of air and clippings

- Less need to clean and remove buildup of material from underside deck

- The depth of the Accel Deep mower deck minimizes the amount of material that escapes from the front of the deck

- Limited amount of material to drift onto the operator and mower deck

- Even flow of material discharged out the chute, less recutting results in larger pieces that are less likely to end up on the operator

- Mulching prevents the discharge of material completely and MulchControl makes mulching a practical solution for most mowing situations.

|

|

MulchControl™ system provides superior mulching performance and rapid conversion

MulchControl™ system provides superior mulching performance and rapid conversion

The optional MulchControl system makes mulching more practical for many mowing situations because it not only does an excellent job of mulching, but it also allows the mower to be easily converted for times when it is more desirable to side discharge or collect the lawn material. Advantages of mulching grass clippings include: - Creates a beautiful looking lawn

- Smaller grass clippings disappear into the lawn canopy

- Reduces fertilizer needs

- Grass clippings are not blown onto the operator, driveways, or flower beds

- No need to dispose of bags of clippings

- The MulchControl system includes an adjustable MulchControl baffle near the discharge chute and fixed baffles to control the flow of material under the deck.

- The MulchControl handle, or an electric one-touch actuator, is on top of the mower deck and is used to open and close the MulchControl baffle.

- When the MulchControl baffle is open, most of the material flows freely out the discharge deflector or into a material collection system.

- When the MulchControl baffle is closed, material stays within the deck and gets chopped into mulch and deposited in the turf.

-

MulchControl is well-suited to the following mowing situations: - For operators who usually mulch, but side discharge when grass gets too long

- For operators who usually side discharge, but would like to close the chute to control clippings in some areas

- For operators who always mulch a main lawn, but often side discharge secondary lawns

- For operators who collect clippings but want to go farther before emptying the material collection system

- When approaching driveways or flower beds where clippings would be undesirable

- When a breeze blows clippings back onto the operator

- For side discharge mowing only the areas of the property where grass is too thick for mulching

- With 48A and 54A Mower Decks, for collecting only the areas of the property where grass is too tall or thick for mulching

-

MULCHCONTROL LIMITATIONS

While in the side discharge mode, MulchControl still mulches about one third of the material. Therefore, the side discharge mode is essentially a partial mulch mode. This can be an advantage when side discharging or bagging, as it helps to reduce the amount of material being discharged. Other times this could work as a disadvantage: - When cutting strong southern grasses, such as Zoysia and Bermuda

- When cutting in wet, high growth conditions, such as those found in the Pacific Northwest United States

- When optimum bagging and lawn cleanup is desired

- 42A Mower Deck requires a MulchControl baffle be removed to install the bagger chute

-

When bagging with MulchControl on a 48A or 54A mower deck, the MulchControl baffle can be opened or closed with the Power Flow™ blower installed. The Power Flow blower runs without material when the baffle is closed.

ELECTRIC ONE-TOUCH MULCHCONTROL ATTACHMENTS

|

Attachment |

Description |

Applications |

| BUC11632 |

42-in. (107-cm) Accel Deep electric one-touch MulchControl |

Model year 2016 and newer X300 Series Tractors* |

| BUC11633 |

48-in. (122-cm) Accel Deep electric one-touch MulchControl |

Model year 2016 and newer X300 and X500 Series Tractors* |

| BUC11634 |

54-in. (137-cm) Accel Deep electric one-touch MulchControl |

Model year 2016 and newer X300 and X500 Series Tractors* | |

|

MulchControl™ system provides superior mulching performance and rapid conversion

MulchControl™ system provides superior mulching performance and rapid conversion

The optional MulchControl system makes mulching more practical for many mowing situations because it not only does an excellent job of mulching, but it also allows the mower to be easily converted for times when it is more desirable to side discharge or collect the lawn material. Advantages of mulching grass clippings include: - Creates a beautiful looking lawn

- Smaller grass clippings disappear into the lawn canopy

- Reduces fertilizer needs

- Grass clippings are not blown onto the operator, driveways, or flower beds

- No need to dispose of bags of clippings

- The MulchControl system includes an adjustable MulchControl baffle near the discharge chute and fixed baffles to control the flow of material under the deck.

- The MulchControl handle is on top of the mower deck and is used to open and close the MulchControl baffle.

- When the MulchControl baffle is open, most of the material flows freely out the discharge deflector or into a material collection system.

- When the MulchControl baffle is closed, material stays within the deck and gets chopped into mulch and deposited in the turf.

-

MulchControl is well-suited to the following mowing situations: - For operators who usually mulch, but side discharge when grass gets too long

- For operators who usually side discharge, but would like to close the chute to control clippings in some areas

- For operators who always mulch a main lawn, but often side discharge secondary lawns

- For operators who collect clippings but want to go farther before emptying the material collection system

-

MulchControl puts the operator in control of the clippings.

MULCHCONTROL LIMITATIONS

While in the side-discharge mode, MulchControl still mulches about one third of the material. Therefore, the side-discharge mode is essentially a partial-mulch mode. This can be an advantage when side discharging or bagging, as it helps to reduce the amount of material being discharged. Other times this could work as a disadvantage: - When cutting strong southern grasses, such as Zoysia and Bermuda

- When cutting in wet, high-growth conditions, such as those found in the Pacific Northwest United States

- When optimum bagging and lawn cleanup is desired

|

|

Snow removal is a strength of lawn tractors

Snow removal is a strength of lawn tractors

An advantage of lawn tractors is their ability to use equipment for snow removal. Lawn tractor owners can add a John Deere snow blower or front blade to make quick work of moving snow whenever the need arises. Weather enclosure and tire-chain attachments add comfort and performance.

Equipment available for snow removal includes: - 44-in. (112-cm) Snow Blower

- 44-in. (112-cm) Front Blade

- 48-in. (122-cm) Front Blade (X394 Tractor only)

- Tire chains or TerraGrip traction belts

- Weather enclosure (available for all X300 Series, except the X350R)

- Weights

|

|

Steering is low-effort sector and pinion system

Steering is low-effort sector and pinion system

A heavy-duty sector and pinion steering system with quality bearings provides easy and precise control for the life of the tractor: - Small, 16-in. (40.6-cm) turning radius provides excellent maneuverability

- Tight turning ability improves mowing efficiency

EASY STEERING

Easy steering is important for an enjoyable mowing experience: -

Large, 14-in. (36-cm) diameter steering wheel for improved leverage -

Large sector gear for improved (higher) steering ratio -

Dual drag links to help equalize the steering loads and reduce steering error -

Ball joints on both ends of the steering tie rods for long life -

Long steering arms to improve the mechanical advantage of the steering system through the full range of motion - Sector gear that pivots on a shaft rather than a bushing to ensure proper gear mesh and eliminate binding

- Greaseable front steering spindles to reduce friction and improve wear over time

|

Integrated hydrostatic transaxle efficiently transmits power to wheels

Integrated hydrostatic transaxle efficiently transmits power to wheels

The Tuff Torq® hydrostatic transaxle encloses the hydrostatic pump and motor rotator groups in the same housing with the differential and axle housings. This design is very efficient and reduces the number of sealing surfaces to minimize the potential for leakage.

Combined with the foot controls, the hydrostatic transmission functions similarly to that of an automatic transmission in an automobile, so the term automatic is often used to describe it: - Use of the latest valve designs has significantly reduced the sound level.

- Large pump and motor rotating groups ensure long life and efficient operation.

|

Controls and display functions are easy to identify and convenient to use

Controls and display functions are easy to identify and convenient to use

The contoured dash has clean, attractive styling and ergonomic controls for easy use: - Controls are color coded and labeled with English words for easy identification by the operator.

- Controls are logically placed and easy to reach.

- The power take-off (PTO) switch allows the operator to get fingers underneath it, like a T-handle, to pull up for easy activation.

- The reverse implement option (RIO) switch is a yellow button.

- The latch control on foot-lift models and hydraulic-lift control on power-lift models and the park brake latch are pivot levers for low effort.

- Cruise control activation is handled by an automotive-style button.

- Separate engine speed and choke controls make starting and warming up the engine easier in cold weather.

- The choke lever is spring loaded to eliminate the chance the tractor will be unintentionally operated with the choke partially closed.

- Functional design of the throttle and choke controls provides good appearance and a comfortable feel.

- Display features dark-cockpit design to minimize operator distractions.

- Display is back lit for night visibility.

- Night visibility is especially useful with snow blower use.

- Hour meter makes it easy to tell when oil changes and other maintenance should be performed.

- Electronic fuel gauge provides real-time fuel level information.

- The X350R has a low fuel light, rather than a fuel gauge, to provide the operator with a noticeable warning when low on fuel.

- A tachometer graphically displays engine speed.

- Target-zone graphics inform the operator of the engine speed range to use for best cut quality.

- An indicator tells the operator when the PTO is operating.

- Bright caution and stop lights capture the operator's attention when important information is on the instrument cluster.

- Damage can be prevented and repair costs can be reduced by addressing problems early.

- Operators are advised of what the problem is if they attempt to operate the mower with unsatisfied PTO, seat, or park brake interlocks.

- The indicators are also useful to identify the reasons the PTO or engine may have shut off when an interlock is unsatisfied.

- Operators are advised if battery voltage is low, normal, or excessive.

- The service indicator light illuminates to indicate a diagnostic error code is stored.

- Onboard diagnostics provides trouble codes for use by trained technicians.

- For example, a technician can test switch functionality and circuit continuity without tools.

|

|

Frame is reliable heavy-duty welded steel

Frame is reliable heavy-duty welded steel

The frame is made of heavy formed and welded steel, reinforced in critical areas for even greater strength: - The frame is formed from 12-gauge, 0.105-in. (2.66-mm) thick material for long life.

- Standard front bumper and hitch plate are formed from 9-gauge, 0.15-in. (3.8-mm) steel and complete the frame assembly.

|

|

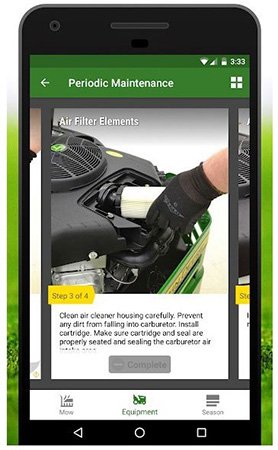

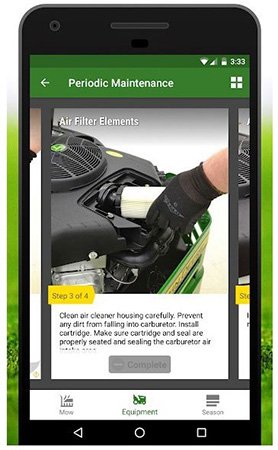

Help maintain your mower and lawn with the MowerPlus™ app and connector

Help maintain your mower and lawn with the MowerPlus™ app and connector

OVERVIEW

Keep a mower running its best and know how it mows with the John Deere MowerPlus app. Simply scan the mower’s barcode to get custom information about the mower.

BENEFITS - Engine hours, fuel level, and battery health (as compatible)

- Mowing history with time, distance, area, and speed

- Current day and five-day weather forecast based on location

- Walk-through setup guides

- Expert mowing tips

- Useful attachments for future purchase

- Periodic maintenance reminders

- Safety instructions

-

BUC10510 MowerPlus Hour Meter Connector is for use with: - Model year 2003 to 2020 100 Series Tractors, including all models with an E, D, LA, or L prefix

- Model year 2015 to 2020 S240 Tractors (serial number -880,000)

- S100, S110, S140, and S220 Tractors

-

BUC10929 MowerPlus Deluxe Smart Connector is for use with: - All S120, S130, S160, S170, and S180 Tractors

- Model year 2021 and newer S240 Tractors (serial number 880,001-)

- Model year 2021 and newer Z515E, Z530M, Z530R, and Z545R (serial number 010,001-)

-

BUC10537 MowerPlus Smart Connector is for use with: - Model year 2016 and newer Select Series X300 and X500 Tractors

-

All the MowerPlus connectors transmit engine hour information to the app, making it easy to track maintenance intervals. The MowerPlus Smart Connector and MowerPlus Deluxe Smart Connector also transmit the fuel level.

MowerPlus connectors require the MowerPlus app on a mobile device to use. The John Deere MowerPlus app and operating system requirements can be found in the mobile device’s app store. The MowerPlus app is only available in the English language, and it is not available in all countries. BUC10510 MowerPlus Hour Meter Connector requires iOS® version 10 or higher and is not compatible with Android™ operating systems.

Apple and App Store are trademarks of Apple, Inc. Google Play and Android are trademarks of Google LLC. iOS is a trademark of Cisco Technology, Inc. used under license by Apple Inc. |

|

Modern styling with functional design enhances appearance and performance

Modern styling with functional design enhances appearance and performance

Smooth, rounded contours present a modern, styled appearance: - Hood styling incorporates efficient full-length air-intake louvers on each side, rather than on the top.

- Cooler engine operation

- Lower operator station sound levels

- Hot air is vented out the front grille, away from the operator.

- The fully enclosed hood is made of molded-in-color material.

- Reduces sound

- Will not rust or dent

- Distinctive grille and large, one-piece fender deck complete the styling package.

Headlights are standard equipment on all models: - Two 27-W bulbs provide excellent lighting for good visibility during evening operation.

- A headlight position on the ignition switch makes it easy to operate the headlights.

- The headlights are designed to provide an optimum lighting pattern for mowing and snow removal.

|

|

Two-year or 120-hour bumper-to-bumper warranty is included

An exclusive 2-year or 120-hour single-source, bumper-to-bumper warranty* is included for all John Deere 100 Series Tractors. |

|

Operator station is comfortable and convenient

Operator station is comfortable and convenient

The operator station is designed for operator comfort and ease of using controls: - A large, 14-in. (36-cm) diameter steering wheel is comfortable to use and minimizes steering effort.

- Full-length foot mats provide comfort for the operator and protect the footrest area.

- Seat travel of 6.6 in. (17 cm) with 15 positions allows the operator to be seated comfortably and easily operate the controls.

- Seat can be easily adjusted fore and aft by the operator while sitting on the seat.

- Open-back design allows air circulation to keep the operator's back cool and dry for a more comfortable ride.

- Grasp at the top of the seat is conveniently located for use when tilting the seat up to protect it from the weather.

- Springs are adjustable fore and aft to any of three positions.

- No tools required

- Allows fine-tuning of the suspension for the operator's weight

- Back position for more support for heavier operators

- Tool tray is designed into the seat base.

- Can be used to store gloves, small tools, etc.

- Provides storage location for Exact Adjust tool and deck-leveling gauge

|