- Monday 8:00AM - 5:00PM

- Tuesday 8:00AM - 5:00PM

- Wednesday 8:00AM - 5:00PM

- Thursday 8:00AM - 5:00PM

- Friday 8:00AM - 5:00PM

- Saturday Closed

- Sunday Closed

2025 John Deere DR12 Twin Row

|

|

MaxEmerge 5 bundles the best of MaxEmerge XP and Pro-Series™ XP row-units to give you a unique planter solution. With more options and configurations, you’ll get difference-making versatility that easily adapts to your ag management plan.

It starts with optimal seed population that drives yield potential. An improved double eliminated helps achieve your desired population with a ride range of crop sizes. Improved side-hill performance of up to ¼ degree ensures you receive the full value of each seed when planting on terraces or rolling terrain. The vacuum air source from the Central Commodity System (CCS™) tank in the meter provides a debris-free environment for increased meter efficiency. The MaxEmerge family of row-units have never seen a more versatile and efficient design until the MaxEmerge 5. The 5-family row-units improve productivity, increase uptime and lower the cost of ownership like never before.

The MaxEmerge 5 row-unit was designed for improved performance and serviceability. The vacuum meter system gently pulls and holds individual seeds to the holes of the seed disk for population control and spacing accuracy, equaling better crop stands and profit. Vacuum seed meters can plant a wide variety of crops and seed types by simply changing seed disks and adjusting vacuum level. Vacuum seed meters are available for planters with MaxEmerge 5 row-units.

Additional features of the vacuum seed meter include:

Vacuum meter hub and latching handle Both the MaxEmerge 5 vacuum meters are equipped with a heavy-duty hub spring and disk latching handle. The spring ensures the seed disk stays properly positioned when operating flat-style seed disks and higher vacuum levels. Proper seed disk positioning means repeatable seed singulation, time after time. The disk-latching handle is designed for easy operation and effortless seed disk changeover. The hub is also machined to tight tolerances to further ensure alignment of metering components. Double eliminator For difficult to singulate seeds, a flat seed disk and double eliminator is a viable alternative to traditional cell-type seed disks. By design, a flat seed disk requires higher levels of vacuum than a cell-type disk because there is no pocket or cell to hold the seed. The higher vacuum level will pull more than one seed to the holes in the seed disk. The double eliminator is set to cover a portion of the hole in the seed disk and is the mechanism to knock multiple seeds away as the disk rotates.

Double eliminators are required with flat-type seed disks only and should not be used with cell-type seed disks. The knockout wheel is also recommended in conjunction with the double eliminator and flat seed disk to ensure seed is ejected from the disk.

Flat and celled type seed metering disks are available to allow planting a wide variety of seed types.

Mini-hopper row-units, which are used only with the CCS, are compatible only with crops that the CCS is approved to plant.

NOTE: Due to small seed size and low planting populations, sugar beets can be planted with mini-hopper style meters by adding hopper extensions and not using the CCS tank. These hopper extensions can also be used for planting test plots. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

CCS seed delivery adds productivity through:

Crops that can be planted with the CCS System include corn, sweet corn, popcorn, cotton, sunflowers, sugar beets, soybeans, and sorghum (milo).

Filling the tanks is convenient due to a central filling location. The staircase and railing provide access to the filling platform between the tanks. Additionally, each tank has an adjustable bin-level sensor to alert the operator when it is time to fill.

A light-emitting diode (LED) fill light package is included on machines equipped with CCS. This feature includes two LED lights conveniently mounted on the railings of the machine. The lights are turned on and off with their own switch located at the bottom of the staircase.

If the seed-carrying vehicle requires hydraulic power to run the unloading system, the auxiliary hydraulic coupler option is available. These couplers are located at the bottom of the staircase and can be coupled under pressure. The system has a separate system filter that ensures the planter hydraulic system remains free of contaminants. CCS system capacities by model:

NOTE: CCS system capacity on 1795 machines are reduced when a fertilizer tank is equipped. NOTE: DB60T and DB120 machines use two 1762-L (50-bu) tanks and one 1233-L (35-bu) tank.

Seed delivery process

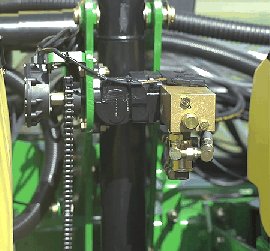

The CCS seed delivery process relies on a hydraulically driven fan to move seed from the CCS tanks to the row-unit hoppers. A flow control valve and gauge, located near the tank, allows for the proper tank pressure setting based on seed type. For normal operation, the CCS functions of fan and agitator control, as well as bin level sensing alerts, are controlled by status of the height switch. The CCS functions are enabled when the machine is lowered and disabled when the machine is raised. In addition, the CCS functions can be engaged for CCS hose cleanout using the switch on the back of the planter when oil flow is present. On models with software-based CCS control, CCS functions can be enabled or disabled through software interface in the cab as well as the switch on the back of the planter.

Air from the fan pressurizes the CCS tanks and delivers seed to the seed hoppers. Airflow enters the seed tanks through a nozzle in the manifold which pressurizes the tank. The air then picks up seed and moves it out the other end of the nozzle into seed delivery hoses. These hoses route the seed toward the hopper. A small amount of seed is traveling in the delivery hoses only when needed.

The hopper fills with seed until the delivery hose (discharge elbow) is covered. Once the opening is restricted, seed flow through the hose stops. Air flowing to the row-unit travels into the hopper and is the source of air for the vacuum system. This provides a much cleaner air source than previous meter designs. As the seed is picked up by the meter and planted, the seed pool shrinks until the end of the delivery hose is uncovered. At that time, the airflow and seed delivery resume and the seed pool in the hopper is replenished.

CCS tank scales for DB Planter models

There are three load cells: two at the rear of the CCS cradle and one at the front. They weigh both tanks as one; individual tank weights cannot be determined.

The load cells and display are made by Digi-Star. They are not on the controller area network (CAN) bus system so they are not integrated into SeedStar™ software in any way. The monitor is sold separately through Digi-Star.

CCS seed cleanout

CCS seed delivery hoses are then purged with air from the CCS fan, and the excess seed is pushed to the individual meters. The vacuum meter door is opened and seed is removed with the supplied catch pan. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The variable-rate drive on the 12Row, 16Row, 18Row, and 24Row integral planter completing packages provide the ultimate planting productivity by utilizing three hydraulic motors to turn the seeding drive shaft. Hydraulic control of the seeding drive allows for on-the-go seeding rate changes right from the display mounted inside the tractor cab. Combine this seeding flexibility with the map-based planting option, and seeding rates adjust automatically based on a prescription map.

The variable-rate drive requires the SeedStar™ 2 monitor and a speed input signal. Either tractor or planter radar may be used, or a global positioning system (GPS) speed signal. The radar speed input signal is recommended. Planter radar is ordered separately. The variable-rate drive offers the following advantages:

Three-width drive disconnect is base equipment on the custom 12Row, 16Row, 18Row, and 24Row integral planter completing packages. This feature is activated by three individual console mounted switches (control box), conveniently located in the tractor cab. The function easily shuts off the planter row-unit seed meters by one, two, or three drive segments independently. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Hydraulic steering for chassis lift system The hydraulic steering assists the operator while backing into the next pass. The implement wheels are steered in the opposite direction of the tractor steering wheels when in reverse. The system is calibrated to steer the lift-assist wheels to the ideal steering angle when turning in reverse and guides the planter from a position sensor mounted to the tractor's front axle. This steering system prevents the lift-assist wheels from casting or spinning around when the direction is changed from forward to reserve. This saves disruption to beds or soil. The hydraulic steering also provides resistance to lift-assist wheels, eliminating vibrations from the wheels while traveling forward, and is most beneficial during transport. Less hydraulic steering for chassis lift system Less lift-assist wheel steering is available to producers who do not need to guide the lift-assist wheels in reverse. This eliminates the need for the position sensor mounted the tractor’s front axle. The less hydraulic steering option does not provide resistance to vibrations from the lift-assist wheels during transport and allows the wheels to caster or spin around during direction changes. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

When you buy John Deere equipment, you expect reliability. You also know that problems can happen, and a product is only as good as the support behind it. That’s why John Deere equipment is prepared with technology that senses potential issues and can alert you and your dealer promptly—in the cab or anywhere you are. John Deere Connected Support is a revolutionary change to support that leverages technology and the connectivity of JDLink™ telematics to prevent downtime and resolve problems faster. These tools decrease downtime by an average of 20 percent, enabling faster responses to unexpected problems and reducing technician trips to your machine. For some issues, unplanned downtime can even be prevented altogether through prediction of the issue. With your permission, John Deere Connected Support:

With more than a decade of experience leveraging connectivity to solve problems, no one else has the experience, tools, and knowledge to keep you running as John Deere and your John Deere dealer can. Connected Support is an in-base feature on all John Deere products with factory- or field-installed JDLink. |

Name |

Link |

| View Product Brochure | Download |

Advance with MaxEmerge™ 5 advantages

Advance with MaxEmerge™ 5 advantages Increase overall productivity with Central Commodity System (CCS™) seed delivery system

Increase overall productivity with Central Commodity System (CCS™) seed delivery system Seed variable-rate drive

Seed variable-rate drive

Lift-assist wheel steering

Lift-assist wheel steering John Deere Connected Support™ prevents downtime and efficiently resolves issues with revolutionary technology-based solutions

John Deere Connected Support™ prevents downtime and efficiently resolves issues with revolutionary technology-based solutions